Reverse Engineering

You just visited the right company at right time. Your search for the reliable reverse engineering consultant ends here. Sunvision the worlds top reverse engineering consultant, has solved the burning and most challenging problems of our clients with cost effective solutions using 3d scanning reverse engineering technology.

Our reverse engineering in mechanical sector is not just limited to the component or product design we also offer the manufacturing assistance for the product and provide a turnkey solution. Our methodology of reverse engineering services are defined as the art of replicating an object, artifact or 3d reverse engineering software with lost document in order to reveal the secrets of design, material, specifications, functions or reverse engineering tools. Our process of Reverse Engineering Consultancy includes taking a system or component conventionally or with help of 3d scanner and then understanding its structural and functional aspects by analyzing the detailed CAD data of the component taken under consideration in 3d scanning reverse engineering services software.

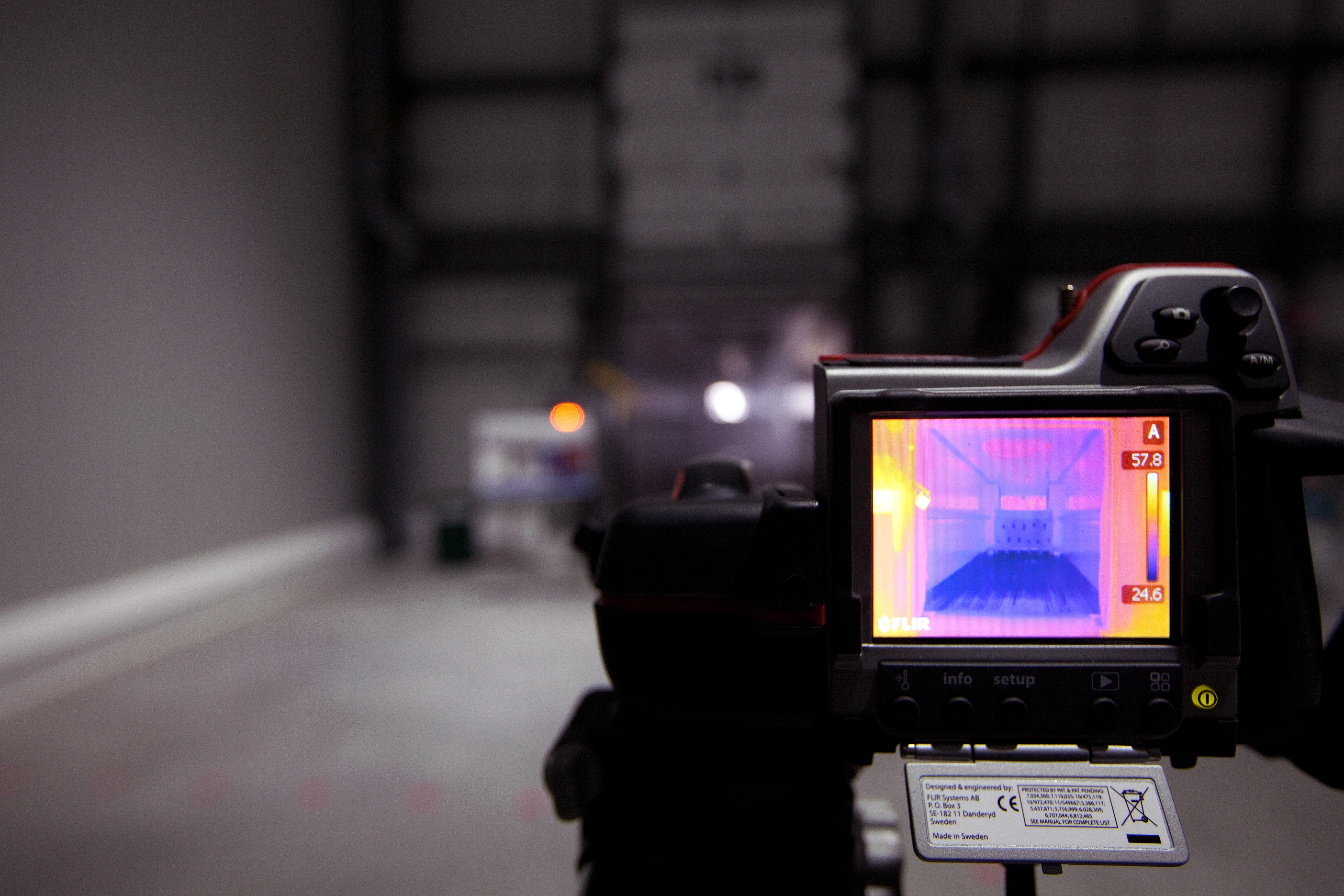

Our Reverse engineering services process also involves digital measuring of component using digitized optical 3d laser scanners (noncontact type or tools for 3d scanner for reverse engineering) or CMM’s (contact type) and then creating a 3D model from the point data obtained using CAD/CAM/CAE or other 3d reverse engineering software.

Our Reverse Engineering is found to be an effective method in case where design modifications have to be imparted in a product whose original CAD model is not available, need to implement a laser scanning technology. It also plays a vital role in wear inspection processes of complex shapes which are if done manually in reverse engineering in mechanical sector are found to be very complex, time consuming and costly. Hence main objective of reverse engineering process is to reduce lead times using 3d scanner so that the manufacturing time can be reduced automatically with 3d scanning reverse engineering services of Sunvision.

Our reverse engineering process contains three major steps which are used to extract knowledge about the design, material, structure, surface qualities, and working conditions of the product etc which make us stand on the top among the other reverse engineering companies. The procedural steps are defined as scanning phase(using 3d scanner for reverse engineering), point processing phase and solid modeling (reverse engineering tools). With our rich experience in reverse engineering we have been incorporated in appropriate reverse engineering mechanical design and manufacturing engineering standards and multiple realistic product constraints with broad knowledge in multiple disciplines such as: Applying knowledge of mathematics, engineering, and science in data analysis and interpretation using 3d reverse engineering technology (3d laser scanner). Using techniques, instruments, and tools in reverse engineering applications, conducting appropriate experiments and tests to obtain the necessary data in 3d reverse engineering. Identifying, formulating, and solving issues related to reverse engineering using laser scanning technology. Understanding legal and ethical responsibilities pertinent to reverse engineering.

Assessing and evaluating documents and fostering attainment of objectives of a reverse engineering project.